1100 Aluminium Coil

Thickness: 0.5mm-170mm

Width: Under 2250mm

Length: Under 11000mm(11m) or by coil

Email: sales@aluminium-sheets.com

Tel & WhatsApp: +86 17719845538

Contact us for free 1100 aluminum Coil samples!

Introduction

1100 Aluminum Alloy Introduction

Aluminum alloy 1100 is a commercially pure aluminum that is soft and ductile. It is the most common aluminum alloy and is often used in the production of products such as kitchen utensils, window frames, and roofing. 1100 aluminium also used in the manufacture of aircraft components and automotive parts. It has excellent corrosion resistance and weldability, and is often used in the production of electrical components.

1100 Aluminum Coil Chemical Composition

| Elements | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al |

| Content (max) | 0.95 | 0.4 | 0.05 | 0.05 | 0.05 | – | 0.1 | – | 0.15 | 99.95 |

Typical Mechanical Properties Of 1100 Aluminium Coil

1100 aluminum alloy is a pure aluminum (99.00% minimum) with excellent electrical conductivity, good formability, and high corrosion resistance.

Tensile Strength: 60 – 95 ksi

Yield Strength: 45 – 70 ksi

Elastic Modulus: 10 x 10^6 psi

Shear Modulus: 4.5 x 10^6 psi

Fatigue Strength: 25 – 40 ksi

Elongation: 14 – 28%

Hardness: 60 – 70 HB

It is important to note that the actual mechanical properties of 1100 aluminum alloy can vary based on the specific temper, heat treatment, and processing conditions used.

1100 Aluminum Alloy Analysis Of Advantages And Disadvantages

Advantages of 1100 Aluminum Alloy:

- Lightweight and has a high strength-to-weight ratio.

- Corrosion resistant and has excellent weldability.

- Easy to form and machine.

- Excellent electrical and thermal conductivity.

Disadvantages of 1100 Aluminum Alloy:

- Not as strong as other aluminum alloys.

- Not suitable for high temperature applications.

- Not as corrosion resistant as other aluminum alloys.

- Not as weldable as other aluminum alloys.

Applications Of 1100 Aluminum alloy

1100 aluminum alloy is widely used in various applications due to its excellent formability, high corrosion resistance, and good electrical conductivity. Some common applications of 1100 aluminum alloy include:

- Architectural applications: Used in the manufacture of roofing, siding, and flashing for buildings.

- Kitchenware: Used in the production of cooking utensils, such as pots and pans, due to its high thermal conductivity.

- Chemical equipment: The corrosion resistance of 1100 aluminum alloy makes it a popular material for the manufacture of chemical storage tanks and reaction vessels.

- Electrical applications: The good electrical conductivity of 1100 aluminum alloy makes it suitable for use in electrical components and wiring.

- Decorative products: Used in the manufacture of various decorative products, such as aluminum foil and jewelry.

- Packaging: Used in the production of aluminum cans, foils, and lids for food packaging.

- Transportation: Used in the manufacture of auto parts, such as trim and fuel tanks, due to its good formability and corrosion resistance.

1100 Aluminum Alloy Features:

1100 aluminum alloy is a pure aluminum (99.00% minimum) that is known for its excellent formability, high corrosion resistance, and good electrical conductivity. Here are some of the key features of 1100 aluminum alloy:

- High electrical conductivity: High electrical conductivity, making it suitable for use in electrical applications.

- Excellent formability: Good formability and can be easily shaped and molded into various forms.

- High corrosion resistance: High resistance to corrosion, making it ideal for use in environments where corrosion is a concern.

- Good thermal conductivity: Good thermal conductivity, making it suitable for use in applications where heat transfer is important.

- Weldability: It is easily weldable, making it suitable for use in applications where welding is required.

- Non-toxic: It is non-toxic, making it suitable for use in applications where food and beverage contact is a concern.

- Lightweight: It is lightweight, making it suitable for use in applications where weight reduction is important.

1100 Aluminum Alloy Market Analysis

1100 Aluminium Coil is a popular material for various applications due to its excellent formability, high corrosion resistance, and good electrical conductivity. Here is a brief analysis of the 1100 aluminum alloy market:

- Growing Demand: The demand for 1100 aluminum alloy is growing due to its widespread use in various applications, including electrical and electronic components, packaging, and construction.

- Increasing Use in Automotive Industry: The use of 1100 aluminum alloy is increasing in the automotive industry due to its good formability, high corrosion resistance, and lightweight nature, which helps to reduce the overall weight of vehicles.

- Asia-Pacific Dominates the Market: The Asia-Pacific region dominates the 1100 aluminum alloy market due to the growing demand for aluminum in the region, as well as the presence of large-scale aluminum producers in countries such as China and India.

- Growing Use in Packaging Industry: The use of 1100 aluminum alloy is growing in the packaging industry due to its excellent formability and high resistance to corrosion, which make it suitable for use in packaging applications.

- Technological Advancements: Technological advancements in aluminum processing techniques are driving the growth of the 1100 aluminum alloy market by improving the quality and efficiency of production processes.

1100 Aluminium Coil Production

- Bauxite Mining: The first step in the production of 1100 aluminum alloy is the mining of bauxite, which is the main source of aluminum.

- Refining: The bauxite ore is refined to produce alumina, which is then further processed to produce aluminum.

- Smelting: The aluminum is produced by melting the alumina in a smelting furnace and refining it to remove impurities.

- Casting: The molten aluminum is then cast into ingots or slabs.

- Rolling: The ingots or slabs are then rolled into sheets, plates, or other desired forms.

- Annealing: The rolled sheets or plates are then subjected to annealing, which involves heating and cooling the aluminum to improve its formability and workability.

- Tempering: The annealed aluminum is then subjected to tempering, which involves heating and cooling the aluminum to improve its mechanical properties.

- Final Processing: The tempered aluminum is then subjected to final processing, such as cutting, stamping, or forming, to produce the desired final product.

FAQ

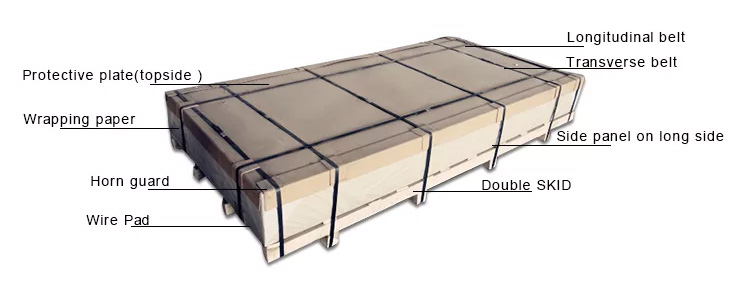

Shipping & Packaging

To ensure that the surface of the aluminium sheets/plates is intact without scratches, we will clamp paper and cover film on the aluminium sheets/plates;

The plastic or kraft paper package is used for moisture-proof and rain proof to ensure that the aluminium sheets/plates is clean and free from dirt during transportation;

We add wooden support and reinforce with steel belt to avoid collision during transportation and ensure the shape of aluminium sheets/plates is unchanged;

Export products are all packaged in wooden cases and brackets marked with fumigation;

Before-sale service

We have full stock and can deliver within short time.

OEM and ODM order are accepted, Any kind of logo printing or design are available.

Good Quality + Factory Price + Quick Response + Reliable Service, is what we are trying best to offer you.

All of our products are produced by our professional workman and we have our high-work-effect foreign trade team, you can totally believe our service.

After choose

We will count cheapest shipping cost and make invoice to you at once.

Check quality again, then send out to you at 5-7 working day after your payment.

Email you the tracking no, and help to chase the parcels until it arrive you.

After-sale service

If you have any question, please contact us freely by E-mail or Telephone.

We will reply you within 24 hours and solve your problem asap.

Hi, I'm Bella. I believe you have seen many websites of aluminum merchants, but you haven't chosen yet. I sincerely suggest that you choose to purchase our products. Not only because I work here.

We are different from ordinary trading companies but a professional aluminum plate manufacturer with a production base. You are welcome to visit at any time! And we are a caring team, I believe that cooperation with us will make you satisfied!

Email: sales@aluminium-sheets.com

Mobile/WhatsApp: +86 17719845538

Leave Your Requirement on Climb aluminum alloy products! We Will Reply You In 12 Hours!