Aluminium is a very strong and lightweight material. It is also highly corrosion resistant, making it an ideal choice for many applications in the automotive, aerospace, and consumer product industries.

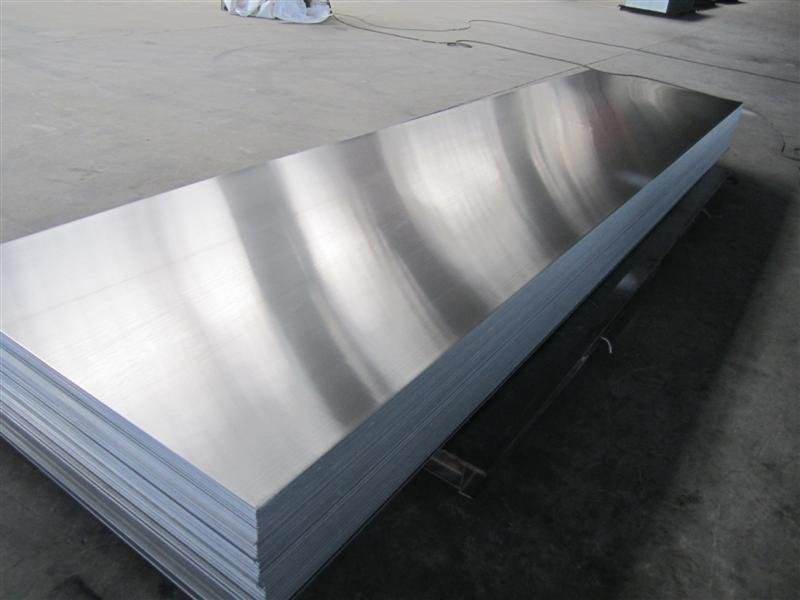

A 2mm aluminium sheet is an essential part of every components’ manufacturing line. It is used to create the majority of the parts, but it is also used as a secondary support structure. This thin sheet of metal can be bent, cut and formed into any shape or form. It has many positive attributes including its ability to be welded and machined in multiple ways.

The main drawback of aluminium alloys is that their strength can be affected by impurities such as silicon or magnesium. Aluminium’s high thermal conductivity means it transfers heat quickly from hot to cool areas during manufacturing processes and in-use conditions. This can result in sudden temperature fluctuations during use (such as when you open a hot cup of coffee), which may cause defects such as cracking or blistering on the surface of your product.

Because commercial grade aluminium sheet has little to no impurities present inside its structure, it tends to be more expensive than other grades with similar levels of purity found on store shelves. Unfortunately this price premium does not always justify the lack of quality impurities found within its structure; therefore buyers who are looking for quality products made from high-purity aluminium should carefully compare prices between different grades to find one with the right balance between cost and quality factors before purchasing any products made from this material type.

Why Your 2mm Aluminum Sheet Is Missing The Mark?

From time to time manufacturers will make changes throughout their production process that affect the composition of materials used throughout certain components – sometimes these changes can alter the properties (mechanical strength) or formability (malleability) of these components after they’re melted together into a finished part. When this happens, there are various tests that manufacturers can perform at multiple stages throughout their manufacturing process to ensure that new batches produced meet desired criteria before being shipped off for sale/distribution